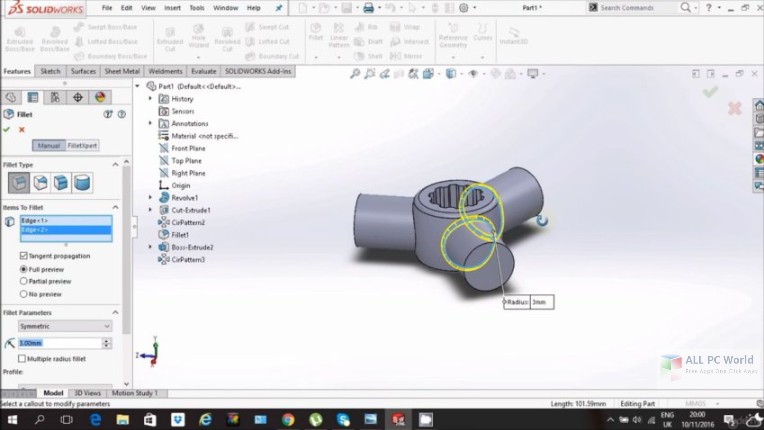

In addition, CAMWorks associativity accelerates new product development by automatically updating manufacturing models with design changes.įor the mold and die industry, Geometric has introduced ElectrodeWorks(TM), an optional electrode design solution that automates the entire process of calculation and design of EDM electrodes including design, management, documentation, and manufacturing. These features make CAMWorks' knowledge-based machining capabilities easier to use, and improves the consistency and quality of the programmed parts.

The Technology Database (TechDB(TM)), that is used to store and apply knowledge based machining information, has been enhanced to simplify the process of creating best machining practices. As part models become increasingly complex, recognizing more features in less time represents huge time savings. The result is fully automatic programming of families of parts, automatic programming of similar features on new parts, and the ability to incorporate manufacturing information directly into the solid model.ĬAMWorks® 2011 has been upgraded to find more features, while reducing computation times by more than 50 percent. Using AFR, CAMWorks identifies the areas to be machined, and then uses its proprietary Technology Database (TechDB(TM)) to generate toolpaths automatically. VoluMill also helps avoid costly collisions and greatly extends the life of machine tools.Īt the heart of CAMWorks 2011 is the world's leading Automatic Feature Recognition (AFR) software, making it the ideal CAM system for programming components. As a result, cutting tool life is dramatically extended and tooling costs can be reduced by over 80 percent.

In addition, VoluMill® allows you to establish and maintain ideal cutting conditions. VoluMill can reduce cycle times by more than 80 percent, thereby increasing production by up to 500 percent. Scottsdale, Arizona, May 3, 2011: Geometric (a leader in developing advanced manufacturing software, announced that it will showcase its fully automatic CNC programming system CAMWorks® 2011 (at Booth #5458, at Eastec 2011, from 17 to 19 May, 2011 in West Springfield, MA, USA.ĬAMWorks 2011 automates the CNC programming process, reduces programming time by as much as 90 percent, and allows design and manufacturing engineers to use a single common database for both product design and final machining.ĬAMWorks 2011 introduces VoluMill®, the ultra-high-performance toolpath generator for 2.5 axis and 3 axis high speed rough milling.

0 kommentar(er)

0 kommentar(er)